Bricks or food? Bihar's construction conundrum

Fed by the river Ganges, the highly fertile soils of the Indian state of Bihar have made the region one of the country’s largest producers of fruits and vegetables. Bihar’s economy remains primarily agrarian, employing almost 80% of the workforce and making up a quarter of the state’s domestic product. But in recent years, a conflict has emerged between agriculture and another of Bihar’s most important industries: construction.

Bihar has about 7,700 red brick kilns which produce approximately 23 billion red bricks annually12. But these bricks are made from fired clay, and that clay is being strip-mined from Bihar’s productive agricultural land – putting a huge dent in agricultural output and food production. Bihar’s red brick industry destroys an estimated 65 million tons3 of fertile soil every year – the equivalent of 300 square km4 of agricultural land. And the problem is not going away. The brick industry is growing rapidly, and land under cultivation for some of the most prominent crops in Bihar has declined significantly during the past few years.

The brick industry is currently based on decentralized, energy intensive, resource depleting and highly polluting production systems using Fixed Chimney Brick Kilns. Beyond stripping fertile soil, the red bricks also pose a threat to local air quality. Firing of these bricks emits large amounts of carbon, soot, coal dust and other harmful gases, which contribute towards climate change and also impact the health of local people.

“ Economic growth cannot come at the expense of environmental and public health, nor should it endanger the jobs of the millions of Bihar agricultural workers, or threaten India’s food security.”

Curbing this challenge is essential for Bihar’s future as one of the food centres of India. Economic growth cannot come at the expense of environmental and public health, nor should it endanger the jobs of the millions of Bihar agricultural workers, or threaten India’s food security. Luckily, there is a solution, which can both protect Bihar’s agricultural land and reduce carbon emissions: the fly ash brick.

Fly ash bricks are made out of a waste product produced in Bihar’s power stations which would otherwise be dumped in landfill or allowed to wash into rivers – creating further pollution. The fly ash is mixed with water and binding agents and then packed into standard house bricks, without the need to mine fertile soil for clay or bake the bricks in polluting kilns.

The Government of Bihar has tried to promote this new cleaner technology with several initiatives in the past few decades, but these have had mixed outcomes. Recently, in early 2018, the Bihar State Pollution Control Board made it mandatory for all existing brick kilns to adopt cleaner technologies for brick making processes. Many red brick kilns units are now moving towards cleaner technologies, by either adopting fly ash brick making processes, or converting their kilns to less-polluting designs such as zig-zag stacks.

Cleaner kilns are a good start, but they don’t solve the problem of fertile soil destruction, and they are still far more polluting that fly-ash production methods. We believe that the state of Bihar must do more to encourage the production and the usage of fly ash bricks, and we’re working with government and local industry to demonstrate the opportunity that fly ash represents: a chance to use waste products productively, lower carbon emissions and air pollution, and providing decent jobs to the local community.

Existing policies are strong: in 2017, the state government mandated that public sector construction projects must use 100% fly ash bricks, and this year went further and banned traditional red clay brick kilns outright. However, these policies are currently only sporadically enforced, despite the huge potential for fly ash.

Bihar currently has 4.1 GW of installed thermal power capacity spread across 4 thermal plants and in 2016-17, these power plants generated 7.39 Million Tons (MT) of fly ash, but only 32.37% (2.39MT) of the generated fly ash was re-used, with the rest presumably being dumped.5 The low rate of fly ash utilization in Bihar clearly indicates the potential for fly ash brick production in Bihar.

There is enough fly ash available to produce about 7 billion bricks per year. If only half of the fly ash generated were actually used for manufacturing fly ash bricks, the green brick sector (i.e. fly ash brick sector) has the potential to:

- Save 8.4 million tons of soil

- Utilize 4.5 million tons of fly ash (waste)

- Save 2.02 million tons of carbon

- Save 0.63 million tons of coal

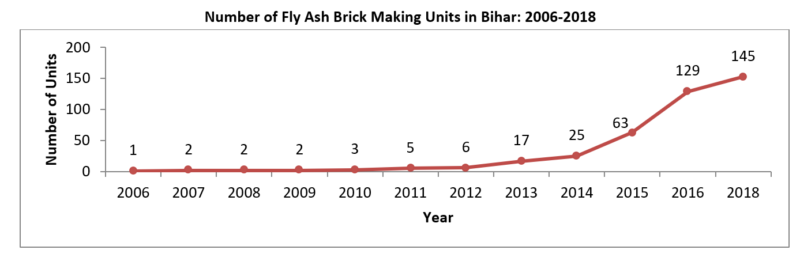

It’s encouraging to see that Bihar’s nascent fly ash brick industry has experienced exponential growth since 2012. State level surveys conducted in the year 2013, 2014 and 2016 have shown that number of fly ash brick units have grown from 17 in 2013 to 129 in 2016 – although the survey conducted in 2016 revealed that only 46 units were operational. The units that were shut down reported lack of market demand as one of the prime reasons of closing, but government construction projects which are mandated to use fly ash bricks have also reported to us that there aren’t enough fly ash bricks in Bihar to meet their usage targets. This tension between supply and demand has been a topic of constant debate in various state level meetings conducted in Bihar.

Recognising this, Development Alternatives in 2018 conducted another detailed survey of all the 38 districts in Bihar to map fly ash bricks units. This survey exercise was different than the previous surveys conducted in 2013 and 2016. The aim of this survey was to map fly ash brick units on an interactive Geographic Information System (GIS). The survey results of 38 districts showed that:

- Bihar has approximately 145 fly ash brick making units

- The number of operational units increased to 76 an increase of 30 units from 2016.

- There were 10 units that were up-coming at the time of survey.

- 52 units were marked as ‘production stalled’, as they were operational only if demand arises, but were not operating at the time of survey

- 2 units had completely closed their operation and disassembled their machines.

Development Alternative’s (DA) continuous research in the brick sector in Bihar has revealed that even though many fly ash brick making units exist, large numbers of these existing fly ash enterprises are either non-functional or have shut down due to lack of market demand. Fly ash brick makers face several barriers to entry, including a lack of market demand, negative mindset regarding fly ash bricks, lack of fiscal incentives, problems with fly ash sourcing and lack of regulation leading to uncertainty and awareness.

To fix this, we’re working together with state government, business coalitions, industry bodies and independent entrepreneurs in both the fly ash and red brick sectors. We want to see better and more cohesive implementation of policies, awareness campaigns to stimulate demand and understanding of fly ash bricks, and capacity building programmes for fly ash entrepreneurs in order to produce good quality fly ash bricks. Watch this space!

- Shruti Issar, Development Alternatives

Footnotes

Average annual brick production of 1 FCBTK is 30 lakh. Assuming all bricks kilns is functional.

1 sq km is equal to 0.22 million ton of soil. Bulk density of soil taken as 1.5g/cu cm and depth of top soil taken as 15 cm